DIFFICULTY: rated at 4, very easy to do but with anything, especially polishing, work + attention to detail X time= results. If you half ass it you get half ass results...that simple.

DIFFICULTY: rated at 4, very easy to do but with anything, especially polishing, work + attention to detail X time= results. If you half ass it you get half ass results...that simple.

1|2|3|4|5|6|7|8|9|10

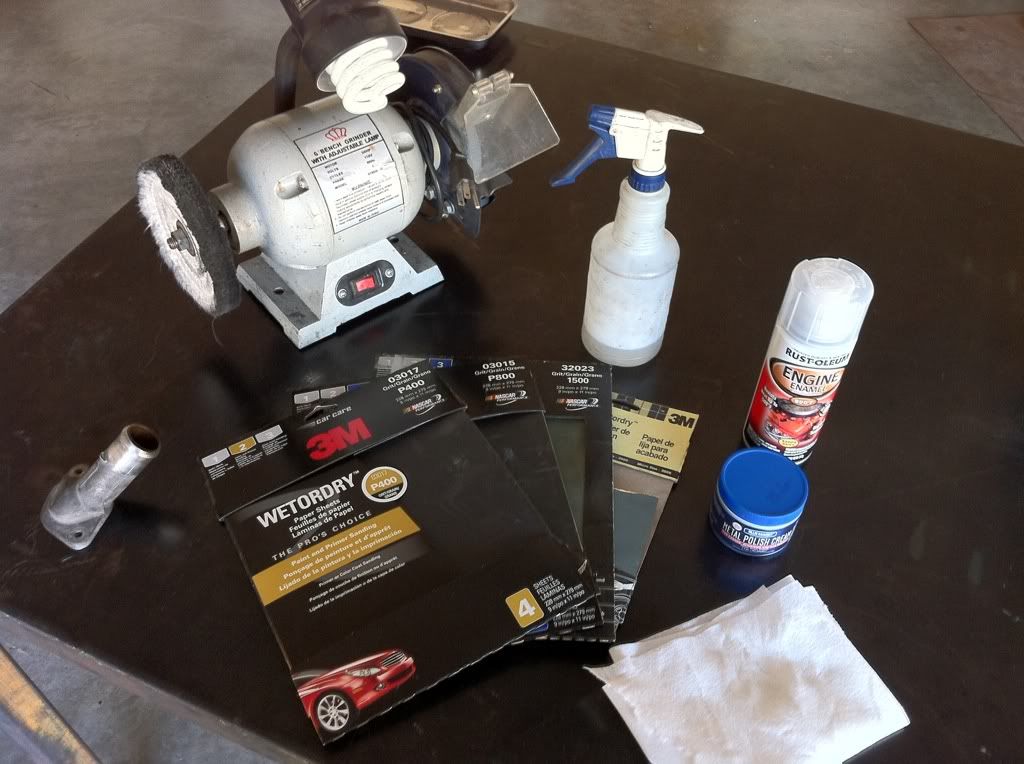

OK today i will start off polishing something very simple...an aluminum thermostat housing. before we get into it lets go over the materials needed to start this project.

- Buffing wheel on a bench grinder (take note of the RPM rating and do not exceed that of the wheel)

- Assortment of 400-1500 grit sand paper (2000 can be used if desired)

- Blue Magic Metal Polish (of course my favorite versatile polish)

- Paper towels or microfiber cloths

- Clear coat (optional and will be explained below)

- Spray bottle with water

- Dremel (optional, can be used to fix surface defects/polish in tight areas).

OK now that we have everything we need lets get started!

OK now that we have everything we need lets get started!Here is the thermostat, it has raised lettering and a casting mark from when it was mass produced. I want to sand those defects down for a smooth look, now this part is optional depending on what you are wanting to do...

Next i grabbed my dremel with a fine grinding wheel on it. this is perfect to sand off the raised lettering and casting marks.

Shown to the right is how it looks after sanding those down, just use your general judgment if you decide to do this.

Shown to the right is how it looks after sanding those down, just use your general judgment if you decide to do this. Next, i wet sanded the whole thermostat down with 400 grit, man this thing is oxidized! i got it from the salvage yard and i suppose its seen its fair share of salt over the years. Keep sanding until all the black specks and imperfections are gone.

Next i did a test polish to see where i stand on the process. Simply apply a thin layer of the polishing compound onto the part, you cant put too much, but if you do it flies all over the place and makes a mess. remember, this part is dangerous!!! be careful how you orientate the part on the buffing wheel allowing no corners to make contact with the wheel in a way as it cause the part to violently kick out. this will cause you to either hurt yourself, or damage the part from being dropped...or both.

Next i did a test polish to see where i stand on the process. Simply apply a thin layer of the polishing compound onto the part, you cant put too much, but if you do it flies all over the place and makes a mess. remember, this part is dangerous!!! be careful how you orientate the part on the buffing wheel allowing no corners to make contact with the wheel in a way as it cause the part to violently kick out. this will cause you to either hurt yourself, or damage the part from being dropped...or both. simply apply pressure and slowly work around the part, you can use the side of the wheel, or at least the corner to remove some compound and that generally gives it a "buff" since its usually dry. hard to explain really without writing a book but once you get here you will see for yourself. experiment with different pressures/angles, no matter how much i try to explain its just one thing i cant really teach, and that is hands on experience.

Here it is fresh from a general buffing. looks a lot better, but see the dark spots? those still need to be sanded out. so keep wet sanding at 400 grit one good time and you should be able to get it out.

Uh oh, looks like i ran into a problem. apparently this piece has some defects from the manufacturing process. There really isn't much i can do about it but sand some, but i cant sand too much or else there will be a low spot...when something like this comes up, you just have to deal with it and try to make it less noticeable or try your luck on a different part.

Notice the side there is a hole, and around the flange too. GM never intended these parts to be polished so you may encounter this, or you may not.

So i sanded some more and that is the best i can do...not as bad as before but lets see if we can make this work.

Next just wet sand thoroughly with 800, then 1500 grit. its the same process as before, just sand it fully then move on the next grit, making sure you got the scratches out from the previous grit of course.

once you do that run it though the buffer and you should get these results.

Now i decided to clear coat this, i used high temp because i thought i would need it being the thermostat sees some heat.

I removed all the grease and cleaned the part very well, then i sprayed on the clear, it did deepen the shine a bit, but its not too bad.

HOWEVER...apparently when high temp clear coat fully cures, it leaves a cloudy finish....so its a BAD idea, not too bad but the only good thing about it is the clear coat does not come off easily, it actually sticks despite how smooth the surface is.

what i do suggest is clear coating with duplicolor clear coat, for regular paint, not high temp. this will NOT dull the shine, but there is a downside, it does peel very easily so this would not be ideal for a part that has anything rubbing against it. and i mean peels easily, a scratch from your nail is enough to make it come off.

I have polished steel before (much more difficult to polish) and used the duplicolor clear coat, it works well despite how delicate it is. so far its held up great. so if clear coating anything due to being lazy to keep it polished, use dupicolor.

Credit goes to beandip on S10 Forum for this How To.